User:Pbbqdd/草稿01

ABEC scale是一个被工业承认的轴承公差标准. 他由Annular Bearing Engineering Committee (ABEC) of the American Bearing Manufacturers Association (ABMA)所制定。ABEC scale旨在提供给符合特定级别精密轴承的标准的轴承制造商的一种尺度规范。需要轴承的设备生产商也必须知道设计零件的尺寸公差以容纳轴承。

共有7种级别的公差规格,从大到小排列是: 1, 3, 5, 7, 9, 11 ,13。ABCE等级越高其精密度,机械效率,高速时性能可能越优越,但是不一定允许组件旋转的太快。ABCE指标并没有明确指出很多重要的指标,比如承载能力,滚珠精密度,材质,材质洛氏硬度,滚珠和滑道的抛光度,噪音,振动,以及润滑剂。由于这些因素,一个ABCE 3级别的轴承可能比ABEC 7的性能更优越。至少ABEC 1的轴承不能被分类为精密轴承,因为它们的公差太大。

尽管不知道与材料,制造和性能有关的因素,该scale也可以作为消费者对他们所期望的轴承类型做出明智决定的指导。

High rated bearings are intended for precision applications like aircraft instruments or surgical equipment. Lower grades are intended for the vast majority of applications such as vehicles, mechanical hobbies, skates, skateboards, fishing reels and industrial machinery. High ABEC rated bearings allow optimal performance of critical applications requiring very high RPM and smooth operation.

ISO's equivalent standard is ISO 492.[1][2]

| ABEC | ISO 492 |

|---|---|

| ABEC 1 | normal class 6X |

| ABEC 3 | class 6 |

| ABEC 5 | class 5 |

| ABEC 7 | class 4 |

| ABEC 9 | class 2 |

| ABEC 11 | class 0 |

| ABEC 13 | class 00 |

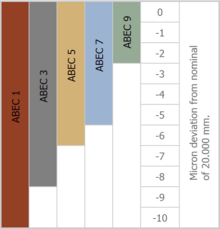

Bearing Tolerance Illustrated[编辑]

To illustrate the,[3] please see the table. The table shows the actual allowable deviations, in micrometers (μm), from nominal for a 20 mm inner diameter bearing. As you can see an ABEC 7 bearing only has a 5 μm tolerance window whereas an ABEC 1 has double that at 10 μm. Please see the tables and PDF’s above for more specific precision bearing tolerancing.

References[编辑]

- ^ ISO 492:2002 – Rolling bearings – Radial bearings – Tolerances. Iso.org (2011-08-23). Retrieved on 2012-08-12.

- ^ Bearing Precision Comparison. Minibearings.com.au. Retrieved on 2012-08-12.

- ^ differences between the ABEC classes provided by GMN Bearings

http://www.abec11.com/products/biltin