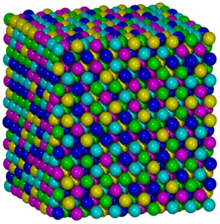

高熵合金

高熵合金(英语:High-entropy alloys、HEAs)简称HEA,通常是由五种或五种以上等量或相对比例金属形成的新型合金。名为“高熵合金”是因为当混合物中存在大量元素混合时的熵增加实质上更高,并且比例更接近相等。[2]

由于高熵合金可能具有许多理想的性质,因此在材料科学及工程上相当受到重视[3]。相对于以往的典型金属合金,合金主要的金属成分可能只有一至两种。例如会以铁为基础,再加入一些微量元素(碳、锰等)来提升其特性,但因此所得的还是以铁为主的合金[3],其他元素比例实际相当低。过往的概念中,若合金中加的金属种类越多,会使其材质脆化,但高熵合金和以往的合金不同,有多种金属却不会脆化,是一种新的材料[1][3][4]。

研究发现有些高熵合金的比强度比传统合金好很多,而且抗断裂能力、抗拉强度、抗腐蚀及抗氧化特性都比传统的合金要好。高熵合金在2004年以前就已问世,但在2010年代才有许多相关的研究[3][5][6][7][8][9]。

发展

[编辑]尽管早在1981年[10]、1996年[11]、以及整个1980年代就考究了理论上可以存在高熵合金。但制造出这些特殊合金,还要到2004年。

据说叶均蔚博士是在1995年驾车穿越新竹乡村时,想出了实际制造高熵合金方法。

高熵合金潜在应用包括用于潜艇、航天器、核武器、核反应堆[12]、喷气式飞机、远程高超音速导弹等等。[13][14]

在叶均蔚博士的论文发表几个月后,布赖恩·康托尔、I. T. H. Chang、P. Knight、A. J. B. Vincent提交了关于高熵合金的独立论文。

叶均蔚也是第一个提出“高熵合金”(英语:High-entropy alloys)一词的人,他将高构型熵归因于稳定固溶体相机制。[15]

尽管布赖恩·康托尔直到2004年叶均蔚论文发表几个月后才发表论文,康托尔其实早在1970年代末1980年代初就完成了该领域的首项工作。康托尔由于不知道叶均蔚的工作,康托尔更喜欢称“高熵合金”为“多组分合金、多元合金”(英语:multicomponent alloys)。康托尔开发了高熵合金FeCrMnNiCo合金,类似的衍生物也被称为康托尔合金。[16]

在将高熵合金和多组分系统归类为单独一类材料之前,核科学家已经研究了一种现在可以归类为高熵合金的系统:在核燃料晶界和裂变气泡处的Mo-Pd-Rh-Ru-Tc粒子。[17]医疗行业对了解这些“五金属粒子”特别感兴趣,因为锝-99m是一种重要医学成像同位素。

定义

[编辑]没有普遍认可的HEA定义。最初将HEA定义为含有至少5种元素且原子百分比5到35的合金。[15]然而后来的研究表明,这个定义还可以扩展。建议只有形成没有金属间相的固溶体的合金才应该被认为是真正的高熵合金,因为有序相的形成会降低系统的熵。[18]一些作者将四组分合金也描述为高熵合金[19]也有建议只有2到4种元素合金满足HEA要求,也算高熵合金[20]或理想气体常数1到1.5之间的混合熵也算[21]“中熵合金”[20]

合成

[编辑]使用现有技术截至2018年[update]难以制造高熵合金,并且通常需要昂贵的材料和特殊的加工技术。[22]

高熵合金主要是使用依赖于金属相方法生产——如果金属在液态、固态、气态下合成。

- 大多数HEA已使用液相方法生产,包括电弧熔化(电弧炉)、感应熔化(感应炉)、布里奇曼-史托巴格法。

- 固态加工通常通过使用高能球磨机的机械合金化完成。这种方法生产的粉末可以使用传统的粉末冶金方法或放电等离子烧结进行加工。这种方法可以生产出使用铸造难以或不可能生产的合金,例如AlLiMgScTi。[23][24][25]

- 气相处理包括溅镀或 分子束外延等工艺,可用于仔细控制不同的元素组成以获得高熵金属[26]或陶瓷膜。[23]

增材制造(立体打印)[27][12]可产出具不同微观结构的合金,潜在地增加强度(1.3吉帕斯卡)、增加延展性[28]

例子

[编辑]高熵合金薄膜例子:

| 合金 | 相态 | 硬度(吉帕斯卡) | 相关模数(吉帕斯卡) | 参考 |

| CoCrFeMnNi | FCC | 5.71 | Er = 172.84 | [30] |

| CoCrFeMnNiAl1.3 | BCC | 8.74 | Er = 167.19 | [30] |

| Al0.3CoCrFeNi | FCC + BCC | 11.09 | E = 186.01 | [31] |

| CrCoCuFeNi | FCC + BCC | 15 | E = 181 | [32] |

| CoCrFeMnNiTi0.2 | FCC | 8.61 | Er = 157.81 | [33] |

| CoCrFeMnNiTi0.8 | 无定形 | 8.99 | Er = 151.42 | [33] |

| CoCrFeMnNiV0.07 | FCC | 7.99 | E = 206.4 | [34] |

| CoCrFeMnNiV1.1 | 无定形 | 8.69 | E = 144.6 | [34] |

| (CoCrFeMnNi)99.5Mo0.5 | FCC | 4.62 | Er = 157.76 | [35] |

| (CoCrFeMnNi)85.4Mo14.6 | 无定形 | 8.77 | Er = 169.17 | [35] |

| (CoCrFeMnNi)92.8Nb7.2 | 无定形 | 8.1 | Er ~105 | [36] |

| TiZrNbHfTa | FCC | 5.4 | — | [37] |

| FeCoNiCrCuAlMn | FCC + BCC | 4.2 | — | [38] |

| FeCoNiCrCuAl0.5 | FCC | 4.4 | — | [38] |

| AlCrMnMoNiZr | 无定形 | 7.2 | E = 172 | [39] |

| AlCrMoTaTiZr | 无定形 | 11.2 | E = 193 | [40] |

| AlCrTiTaZr | 无定形 | 9.3 | E = 140 | [41] |

| AlCrMoNbZr | BCC + 无定形 | 11.8 | — | [42] |

| AlCrNbSiTiV | 无定形 | 10.4 | E = 177 | [43] |

| AlCrSiTiZr | 无定形 | 11.5 | E ~206 | [44] |

| CrNbSiTaZr | 无定形 | 20.12 | — | [45] |

| CrNbSiTiZr | 无定形 | 9.6 | E = 179.7 | [46] |

| AlFeCrNiMo | BCC | 4.98 | — | [47] |

| CuMoTaWV | BCC | 19 | E = 259 | [48] |

| TiVCrZrHf | 无定形 | 8.3 | E = 104.7 | [49] |

| ZrTaNbTiW | 无定形 | 4.7 | E = 120 | [50] |

| TiVCrAlZr | 无定形 | 8.2 | E = 128.9 | [51] |

| FeCoNiCuVZrAl | 无定形 | 8.6 | E = 153 | [52] |

| 合金 | RN (%) | 相态 | 硬度(吉帕斯卡) | 相关模数(吉帕斯卡) | 参考 |

| (FeCoNiCuVZrAl)N | 30 | 无定形 | 12 | E = 166 | [52] |

| (TiZrNbHfTa)N | 25 | FCC | 32.9 | — | [37] |

| (TiVCrAlZr)N | 50 | FCC | 11 | E = 151 | [51] |

| (AlCrTaTiZr)N | 14 | FCC | 32 | E = 368 | [41] |

| (FeCoNiCrCuAl0.5)N | 33.3 | 无定形 | 10.4 | — | [38] |

| (FeCoNiCrCuAlMn)N | 23.1 | 无定形 | 11.8 | — | [38] |

| (AlCrMnMoNiZr)N | 50 | FCC | 11.9 | E = 202 | [39] |

| (TiVCrZrHf)N | 3.85 | FCC | 23.8 | E = 267.3 | [49] |

| (NbTiAlSiW)N | 16.67 | 无定形 | 13.6 | E = 154.4 | [53] |

| (NbTiAlSi)N | 16.67 | FCC | 20.5 | E = 206.8 | |

| (AlCrNbSiTiV)N | 5 | FCC | 35 | E ~ 337 | [43] |

| 28 | FCC | 41 | E = 360 | ||

| (AlCrTaTiZr)N | 50 | FCC | 36 | E = 360 | [54] |

| (Al23.1Cr30.8Nb7.7Si7.7Ti30.7)N50 | — | FCC | 36.1 | E ~ 430 | [55] |

| (Al29.1Cr30.8Nb11.2Si7.7Ti21.2)N50 | FCC | 36.7 | E ~ 380 | ||

| (AlCrSiTiZr)N | 5 | 无定形 | 17 | E ~ 232 | [44] |

| 30 | FCC | 16 | E ~ 232 | ||

| (AlCrMoTaTiZr)N | 40 | FCC | 40.2 | E = 420 | [40] |

| (AlCrTaTiZr)N | 50 | FCC | 35 | E = 350 | [56] |

| (CrTaTiVZr)N | 20 | FCC | 34.3 | E ~ 268 | [57] |

| (CrNbTiAlV)N | 67.86 | FCC | 35.3 | E = 353.7 | [58] |

| (HfNbTiVZr)N | 33.33 | FCC | 7.6 | E = 270 | [59] |

参考

[编辑]- ^ 1.0 1.1 Wang, Shaoqing. Atomic Structure Modeling of Multi-Principal-Element Alloys by the Principle of Maximum Entropy. Entropy. 13 December 2013, 15 (12): 5536–5548 [2016-10-20]. Bibcode:2013Entrp..15.5536W. doi:10.3390/e15125536. (原始内容存档于2016-04-21). HTML full text article available

- ^ Ye, Y.F.; Wang, Q.; Lu, J.; Liu, C.T.; Yang, Y. High-entropy alloy: challenges and prospects. Materials Today. July 2016, 19 (6): 349–362. doi:10.1016/j.mattod.2015.11.026

.

.

- ^ 3.0 3.1 3.2 3.3 Tsai, Ming-Hung; Yeh, Jien-Wei. High-Entropy Alloys: A Critical Review. Materials Research Letters. 30 April 2014, 2 (3): 107–123. doi:10.1080/21663831.2014.912690. Free PDF download.

- ^ 【央廣RTI】「高熵合金」打破多元素合金易脆迷思. [2016-10-21]. (原始内容存档于2016-10-21).

- ^ Lavine, Marc S. A metal alloy that is stronger when cold. Science. 2014, 345: 1131 [9 January 2015]. Bibcode:2014Sci...345Q1131L. doi:10.1126/science.345.6201.1131-b. (原始内容存档于2015-09-24).

- ^ Shipman, Matt. New 'high-entropy' alloy is as light as aluminum, as strong as titanium alloys. Phys.org. 10 December 2014 [9 January 2015]. (原始内容存档于2019-04-19).

- ^ Youssef, Khaled M.; Zaddach, Alexander J.; Niu, Changning; Irving, Douglas L.; Koch, Carl C. A Novel Low-Density, High-Hardness, High-entropy Alloy... (Free PDF download). Materials Research Letters. 9 December 2014: 1. doi:10.1080/21663831.2014.985855.

- ^ Yarris, Lyn. A metallic alloy that is tough and ductile at cryogenic temperatures. Berkeley Lab News Center (University of California, Berkeley). 4 September 2014 [9 January 2015]. (原始内容存档于2016-04-07).

- ^ Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E. H.; George, E. P.; Ritchie, R. O. A fracture-resistant high-entropy alloy for cryogenic applications (Free PDF download). Science (AAAS). 5 September 2014, 345 (6201): 1153–1158 [9 January 2015]. Bibcode:2014Sci...345.1153G. PMID 25190791. doi:10.1126/science.1254581. (原始内容存档 (PDF)于2017-01-27).

- ^ Vincent AJB; Cantor B: part II thesis, University of Sussex (1981).

- ^ Huang KH, Yeh JW. A study on multicomponent alloy systems containing equal-mole elements [M.S. thesis]. Hsinchu: National Tsing Hua University; 1996.

- ^ 12.0 12.1 Sonal, Sonal; Lee, Jonghyun. Recent Advances in Additive Manufacturing of High Entropy Alloys and Their Nuclear and Wear-Resistant Applications. Metals. December 2021, 11 (12): 1980. doi:10.3390/met11121980

.

.

- ^ Wei-han, Chen. Taiwanese researcher gets special 'Nature' coverage - Taipei Times. The Taipei Times. 10 June 2016 [2022-09-03]. (原始内容存档于2022-04-07).

- ^ Yeh, Jien Wei; Chen, Yu Liang; Lin, Su Jien; Chen, Swe Kai. High-Entropy Alloys – A New Era of Exploitation. Materials Science Forum. November 2007, 560: 1–9. S2CID 137011733. doi:10.4028/www.scientific.net/MSF.560.1.

- ^ 15.0 15.1 Yeh, J.-W.; Chen, S.-K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Advanced Engineering Materials. May 2004, 6 (5): 299–303. S2CID 137380231. doi:10.1002/adem.200300567.

- ^ Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Materials Science and Engineering: A. July 2004,. 375-377: 213–218. doi:10.1016/j.msea.2003.10.257.

- ^ Middleburgh, S. C.; King, D. M.; Lumpkin, G. R. Atomic scale modelling of hexagonal structured metallic fission product alloys. Royal Society Open Science. April 2015, 2 (4): 140292. Bibcode:2015RSOS....2n0292M. PMC 4448871

. PMID 26064629. doi:10.1098/rsos.140292.

. PMID 26064629. doi:10.1098/rsos.140292.

- ^ Otto, F.; Yang, Y.; Bei, H.; George, E.P. Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys. Acta Materialia. April 2013, 61 (7): 2628–2638 [2022-09-03]. Bibcode:2013AcMat..61.2628O. doi:10.1016/j.actamat.2013.01.042. (原始内容存档于2022-09-03).

- ^ Zou, Yu; Maiti, Soumyadipta; Steurer, Walter; Spolenak, Ralph. Size-dependent plasticity in an Nb25Mo25Ta25W25 refractory high-entropy alloy. Acta Materialia. February 2014, 65: 85–97. Bibcode:2014AcMat..65...85Z. doi:10.1016/j.actamat.2013.11.049.

- ^ 20.0 20.1 Gali, A.; George, E.P. Tensile properties of high- and medium-entropy alloys. Intermetallics. August 2013, 39: 74–78 [2022-09-03]. doi:10.1016/j.intermet.2013.03.018. (原始内容存档于2022-09-03).

- ^ Miracle, Daniel; Miller, Jonathan; Senkov, Oleg; Woodward, Christopher; Uchic, Michael; Tiley, Jaimie. Exploration and Development of High Entropy Alloys for Structural Applications. Entropy. 10 January 2014, 16 (1): 494–525. Bibcode:2014Entrp..16..494M. doi:10.3390/e16010494

.

.

- ^ Johnson, Duane; Millsaps, Laura. Ames Lab takes the guesswork out of discovering new high-entropy alloys. Ames Laboratory News (U.S. Dept. of Energy). 1 May 2018 [10 December 2018]. (原始内容存档于2019-03-30).

high-entropy alloys are notoriously difficult to make, requiring expensive materials and specialty processing techniques. Even then, attempts in a laboratory don't guarantee that a theoretically possible compound is physically possible, let alone potentially useful.

- ^ 23.0 23.1 23.2 Zhang, Yong; Zuo, Ting Ting; Tang, Zhi; Gao, Michael C.; Dahmen, Karin A.; Liaw, Peter K.; Lu, Zhao Ping. Microstructures and properties of high-entropy alloys. Progress in Materials Science. April 2014, 61: 1–93. doi:10.1016/j.pmatsci.2013.10.001.

- ^ Youssef, Khaled M.; Zaddach, Alexander J.; Niu, Changning; Irving, Douglas L.; Koch, Carl C. A Novel Low-Density, High-Hardness, High-entropy Alloy with Close-packed Single-phase Nanocrystalline Structures. Materials Research Letters. 9 December 2014, 3 (2): 95–99. doi:10.1080/21663831.2014.985855

.

.

- ^ Ji, Wei; Wang, Weimin; Wang, Hao; Zhang, Jinyong; Wang, Yucheng; Zhang, Fan; Fu, Zhengyi. Alloying behavior and novel properties of CoCrFeNiMn high-entropy alloy fabricated by mechanical alloying and spark plasma sintering. Intermetallics. January 2015, 56: 24–27. doi:10.1016/j.intermet.2014.08.008.

- ^ Zou, Yu; Ma, Huan; Spolenak, Ralph. Ultrastrong ductile and stable high-entropy alloys at small scales. Nature Communications. 10 July 2015, 6 (1): 7748. Bibcode:2015NatCo...6.7748Z. PMC 4510962

. PMID 26159936. doi:10.1038/ncomms8748

. PMID 26159936. doi:10.1038/ncomms8748  .

.

- ^ Chaudhary, V.; Mantri, S. A.; Ramanujan, R. V.; Banerjee, R. Additive manufacturing of magnetic materials. Progress in Materials Science. 2020-10-01, 114: 100688. ISSN 0079-6425. doi:10.1016/j.pmatsci.2020.100688 (英语).

- ^ Irving, Michael. 3D-printable 5-metal alloy proves ultra-strong but ductile. New Atlas. 2022-08-10 [2022-08-10]. (原始内容存档于2022-12-13) (美国英语).

- ^ Yao, Chen-Zhong; Zhang, Peng; Liu, Meng; Li, Gao-Ren; Ye, Jian-Qing; Liu, Peng; Tong, Ye-Xiang. Electrochemical preparation and magnetic study of Bi–Fe–Co–Ni–Mn high-entropy alloy. Electrochimica Acta. November 2008, 53 (28): 8359–8365. doi:10.1016/j.electacta.2008.06.036.

- ^ 30.0 30.1 Hsu, Ya-Chu; Li, Chia-Lin; Hsueh, Chun-Hway. Effects of Al Addition on Microstructures and Mechanical Properties of CoCrFeMnNiAlx High Entropy Alloy Films. Entropy. 2019-12-18, 22 (1): 2. Bibcode:2019Entrp..22....2H. ISSN 1099-4300. PMC 7516440

. PMID 33285777. doi:10.3390/e22010002

. PMID 33285777. doi:10.3390/e22010002  .

.

- ^ Liao, Wei-Bing; Zhang, Hongti; Liu, Zhi-Yuan; Li, Pei-Feng; Huang, Jian-Jun; Yu, Chun-Yan; Lu, Yang. High Strength and Deformation Mechanisms of Al0.3CoCrFeNi High-Entropy Alloy Thin Films Fabricated by Magnetron Sputtering. Entropy. 2019-02-04, 21 (2): 146. Bibcode:2019Entrp..21..146L. ISSN 1099-4300. PMC 7514628

. PMID 33266862. doi:10.3390/e21020146

. PMID 33266862. doi:10.3390/e21020146  .

.

- ^ Shaginyan, L. R.; Britun, V. F.; Krapivka, N. A.; Firstov, S. A.; Kotko, A. V.; Gorban, V. F. The Properties of Cr–Co–Cu–Fe–Ni Alloy Films Deposited by Magnetron Sputtering. Powder Metallurgy and Metal Ceramics. 2018-09-01, 57 (5): 293–300. ISSN 1573-9066. S2CID 139253120. doi:10.1007/s11106-018-9982-0 (英语).

- ^ 33.0 33.1 Hsu, Ya-Chu; Li, Chia-Lin; Hsueh, Chun-Hway. Modifications of microstructures and mechanical properties of CoCrFeMnNi high entropy alloy films by adding Ti element. Surface and Coatings Technology. 2020-10-15, 399: 126149. ISSN 0257-8972. S2CID 225592198. doi:10.1016/j.surfcoat.2020.126149 (英语).

- ^ 34.0 34.1 Fang, Shuang; Wang, Cheng; Li, Chia-Lin; Luan, Jun-Hua; Jiao, Zeng-Bao; Liu, Chain-Tsuan; Hsueh, Chun-Hway. Microstructures and mechanical properties of CoCrFeMnNiVx high entropy alloy films. Journal of Alloys and Compounds. 2020-04-15, 820: 153388. ISSN 0925-8388. S2CID 213937088. doi:10.1016/j.jallcom.2019.153388 (英语).

- ^ 35.0 35.1 Huang, Tzu-Hsuan; Hsueh, Chun-Hway. Microstructures and mechanical properties of (CoCrFeMnNi)100-xMox high entropy alloy films. Intermetallics. 2021-08-01, 135: 107236. ISSN 0966-9795. S2CID 236239363. doi:10.1016/j.intermet.2021.107236 (英语).

- ^ Liang, Yu-Hsuan; Li, Chia-Lin; Hsueh, Chun-Hway. Effects of Nb Addition on Microstructures and Mechanical Properties of Nbx-CoCrFeMnNi High Entropy Alloy Films. Coatings. 2021-12-14, 11 (12): 1539. ISSN 2079-6412. doi:10.3390/coatings11121539

.

.

- ^ 37.0 37.1 Braic, V.; Vladescu, Alina; Balaceanu, M.; Luculescu, C. R.; Braic, M. Nanostructured multi-element (TiZrNbHfTa)N and (TiZrNbHfTa)C hard coatings. Surface and Coatings Technology. Proceedings of Symposium K on Protective Coatings and Thin Films, E-MRS 2011 Conference. 2012-10-25, 211: 117–121. ISSN 0257-8972. doi:10.1016/j.surfcoat.2011.09.033 (英语).

- ^ 38.0 38.1 38.2 38.3 Chen, T. K.; Shun, T. T.; Yeh, J. W.; Wong, M. S. Nanostructured nitride films of multi-element high-entropy alloys by reactive DC sputtering. Surface and Coatings Technology. Proceedings of the 31st International Conference on Metallurgical Coatings and Thin Films. 2004-11-01,. 188-189: 193–200. ISSN 0257-8972. doi:10.1016/j.surfcoat.2004.08.023 (英语).

- ^ 39.0 39.1 Ren, Bo; Shen, Zigang; Liu, Zhongxia. Structure and mechanical properties of multi-element (AlCrMnMoNiZr)Nx coatings by reactive magnetron sputtering. Journal of Alloys and Compounds. 2013-05-25, 560: 171–176. ISSN 0925-8388. doi:10.1016/j.jallcom.2013.01.148 (英语).

- ^ 40.0 40.1 Cheng, Keng-Hao; Lai, Chia-Han; Lin, Su-Jien; Yeh, Jien-Wei. Structural and mechanical properties of multi-element (AlCrMoTaTiZr)Nx coatings by reactive magnetron sputtering. Thin Solid Films. 2011-03-01, 519 (10): 3185–3190. Bibcode:2011TSF...519.3185C. ISSN 0040-6090. doi:10.1016/j.tsf.2010.11.034 (英语).

- ^ 41.0 41.1 Lai, Chia-Han; Lin, Su-Jien; Yeh, Jien-Wei; Chang, Shou-Yi. Preparation and characterization of AlCrTaTiZr multi-element nitride coatings. Surface and Coatings Technology. 2006-12-04, 201 (6): 3275–3280. ISSN 0257-8972. doi:10.1016/j.surfcoat.2006.06.048 (英语).

- ^ Zhang, W.; Tang, R.; Yang, Z. B.; Liu, C. H.; Chang, H.; Yang, J. J.; Liao, J. L.; Yang, Y. Y.; Liu, N. Preparation, structure, and properties of high-entropy alloy multilayer coatings for nuclear fuel cladding: A case study of AlCrMoNbZr/(AlCrMoNbZr)N. Journal of Nuclear Materials. 2018-12-15, 512: 15–24. Bibcode:2018JNuM..512...15Z. ISSN 0022-3115. S2CID 105282834. doi:10.1016/j.jnucmat.2018.10.001 (英语).

- ^ 43.0 43.1 Huang, Ping-Kang; Yeh, Jien-Wei. Effects of nitrogen content on structure and mechanical properties of multi-element (AlCrNbSiTiV)N coating. Surface and Coatings Technology. 2009-03-25, 203 (13): 1891–1896. ISSN 0257-8972. doi:10.1016/j.surfcoat.2009.01.016 (英语).

- ^ 44.0 44.1 Hsueh, Hwai-Te; Shen, Wan-Jui; Tsai, Ming-Hung; Yeh, Jien-Wei. Effect of nitrogen content and substrate bias on mechanical and corrosion properties of high-entropy films (AlCrSiTiZr)100−xNx. Surface and Coatings Technology. 2012-05-25, 206 (19): 4106–4112. ISSN 0257-8972. doi:10.1016/j.surfcoat.2012.03.096 (英语).

- ^ Kao, W. H.; Su, Y. L.; Horng, J. H.; Wu, H. M. Effects of carbon doping on mechanical, tribological, structural, anti-corrosion and anti-glass-sticking properties of CrNbSiTaZr high entropy alloy coatings. Thin Solid Films. 2021-01-01, 717: 138448. Bibcode:2021TSF...717m8448K. ISSN 0040-6090. S2CID 229423367. doi:10.1016/j.tsf.2020.138448 (英语).

- ^ Yu, Xu; Wang, Junjun; Wang, Linqing; Huang, Weijiu. Fabrication and characterization of CrNbSiTiZr high-entropy alloy films by radio-frequency magnetron sputtering via tuning substrate bias. Surface and Coatings Technology. 2021-04-25, 412: 127074. ISSN 0257-8972. S2CID 233695035. doi:10.1016/j.surfcoat.2021.127074 (英语).

- ^ Zeng, Qunfeng; Xu, Yating. A comparative study on the tribocorrosion behaviors of AlFeCrNiMo high entropy alloy coatings and 304 stainless steel. Materials Today Communications. 2020-09-01, 24: 101261. ISSN 2352-4928. S2CID 219474551. doi:10.1016/j.mtcomm.2020.101261 (英语).

- ^ Sajid, Alvi. Synthesis and Characterization of High Entropy Alloy and Coating. ISBN 978-91-7790-395-6. OCLC 1102485976.

- ^ 49.0 49.1 Liang, Shih-Chang; Tsai, Du-Cheng; Chang, Zue-Chin; Sung, Huan-Shin; Lin, Yi-Chen; Yeh, Yi-Jung; Deng, Min-Jen; Shieu, Fuh-Sheng. Structural and mechanical properties of multi-element (TiVCrZrHf)N coatings by reactive magnetron sputtering. Applied Surface Science. 2011-10-15, 258 (1): 399–403. Bibcode:2011ApSS..258..399L. ISSN 0169-4332. doi:10.1016/j.apsusc.2011.09.006 (英语).

- ^ Feng, Xingguo; Tang, Guangze; Ma, Xinxin; Sun, Mingren; Wang, Liqin. Characteristics of multi-element (ZrTaNbTiW)N films prepared by magnetron sputtering and plasma based ion implantation. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms. 2013-04-15, 301: 29–35. Bibcode:2013NIMPB.301...29F. ISSN 0168-583X. doi:10.1016/j.nimb.2013.03.001 (英语).

- ^ 51.0 51.1 Chang, Zue-Chin; Liang, Shih-Chang; Han, Sheng; Chen, Yi-Kun; Shieu, Fuh-Sheng. Characteristics of TiVCrAlZr multi-element nitride films prepared by reactive sputtering. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms. 2010-08-15, 268 (16): 2504–2509. Bibcode:2010NIMPB.268.2504C. ISSN 0168-583X. doi:10.1016/j.nimb.2010.05.039 (英语).

- ^ 52.0 52.1 Liu, L.; Zhu, J. B.; Hou, C.; Li, J. C.; Jiang, Q. Dense and smooth amorphous films of multicomponent FeCoNiCuVZrAl high-entropy alloy deposited by direct current magnetron sputtering. Materials & Design. 2013-04-01, 46: 675–679. ISSN 0261-3069. doi:10.1016/j.matdes.2012.11.001 (英语).

- ^ Sheng, Wenjie; Yang, Xiao; Wang, Cong; Zhang, Yong. Nano-Crystallization of High-Entropy 無定形 NbTiAlSiWxNy Films Prepared by Magnetron Sputtering. Entropy. 2016-06-13, 18 (6): 226. Bibcode:2016Entrp..18..226S. ISSN 1099-4300. doi:10.3390/e18060226

.

.

- ^ Lai, Chia-Han; Lin, Su-Jien; Yeh, Jien-Wei; Davison, Andrew. Effect of substrate bias on the structure and properties of multi-element (AlCrTaTiZr)N coatings. Journal of Physics D: Applied Physics. 2006-11-07, 39 (21): 4628–4633. Bibcode:2006JPhD...39.4628L. ISSN 0022-3727. doi:10.1088/0022-3727/39/21/019.

- ^ Hsieh, Ming-Hsiao; Tsai, Ming-Hung; Shen, Wan-Jui; Yeh, Jien-Wei. Structure and properties of two Al–Cr–Nb–Si–Ti high-entropy nitride coatings. Surface and Coatings Technology. 2013-04-25, 221: 118–123. ISSN 0257-8972. doi:10.1016/j.surfcoat.2013.01.036 (英语).

- ^ Lai, Chia-Han; Tsai, Ming-Hung; Lin, Su-Jien; Yeh, Jien-Wei. Influence of substrate temperature on structure and mechanical, properties of multi-element (AlCrTaTiZr)N coatings. Surface and Coatings Technology. 2007-05-21, 201 (16): 6993–6998. ISSN 0257-8972. doi:10.1016/j.surfcoat.2007.01.001 (英语).

- ^ Chang, Zue-Chin; Liang, Jun-Yang. Oxidation Behavior and Structural Transformation of (CrTaTiVZr)N Coatings. Coatings. 2020-04-22, 10 (4): 415. ISSN 2079-6412. doi:10.3390/coatings10040415

.

.

- ^ Zhang, Cunxiu; Lu, Xiaolong; Wang, Cong; Sui, Xudong; Wang, Yanfang; Zhou, Haibin; Hao, Junying. Tailoring the microstructure, mechanical and tribocorrosion performance of (CrNbTiAlV)Nx high-entropy nitride films by controlling nitrogen flow. Journal of Materials Science & Technology. 2022-04-30, 107: 172–182. ISSN 1005-0302. S2CID 244583979. doi:10.1016/j.jmst.2021.08.032 (英语).

- ^ Johansson, Kristina; Riekehr, Lars; Fritze, Stefan; Lewin, Erik. Multicomponent Hf-Nb-Ti-V-Zr nitride coatings by reactive magnetron sputter deposition. Surface and Coatings Technology. 2018-09-15, 349: 529–539. ISSN 0257-8972. S2CID 103303702. doi:10.1016/j.surfcoat.2018.06.030 (英语).