冷卻塔

冷卻塔(英語:cooling tower)是將水蒸氣冷卻成較低溫的水,將系統的废热排到大气层的排熱裝置。冷卻塔可能用蒸發的方式釋放水蒸氣中的熱,將工作流體冷卻到接近湿球温度,也有一種是「閉迴路乾冷卻塔」(closed circuit dry cooling towers),只利用空氣將工作流體冷卻到接近乾球温度。

冷卻塔常見的應用包括冷卻許多工廠中的循環冷卻用水,這些工廠包括有煉油廠、石油化工产品及其他化學工廠、热力发电厂及核电厂。小型的冷卻水塔也用在大樓中的冷氣。冷卻塔可以依讓空氣進入塔中的方式來分類:主要的分類有自然对流及強制對流冷卻塔。

冷卻塔的大小依應用而不同,小的有可以放在大樓屋頂的冷卻水塔,大的則是大型的雙曲塔,高可以到200公尺,直徑則是100公尺,也有可能是長方形的結構,長80公尺,高40公尺。雙曲塔有用在核能發電廠的冷卻塔[1],也有用在一些火力發電廠,甚至是大型的化工廠或其他工廠。大多數的冷卻塔其實體積很小,例如在大樓樓頂,中央空調系統的冷卻水塔。

歷史[编辑]

冷卻塔是在19世紀時開始使用,當時為了配合蒸汽机使用,需要對應的冷凝器[2]。冷凝器會以各種方式將冷凝汽缸或渦輪機產生的蒸氣,冷卻凝結成較低溫的水。這可以減少背壓,減少蒸氣消耗量以及燃料的消耗,同時也可以提昇功率,並且使鍋爐的水可以循環使用[3]。不過冷凝器需要充足的冷卻水供應,若沒有足夠的冷卻水,無法實現冷凝器[4][5]。估計在2040至2069年時,陸上加工廠及發電廠所消耗的冷卻水會減少大部份火力發電廠的產生的電力[6]。在船用蒸汽機上冷卻水的來源不是問題,但在陸地上的系統就有許多的限制。

在二十世紀起,已針對沒有足夠水源的地區開發了幾種以蒸發方式冷卻水的方式,這些方式也可以用在水源供應可能不足的城市地區[2][5]。若是有足夠可用土地的地區,可能會用冷卻池的方式冷卻,若是土地不足,可能就會用冷卻塔[4][7]。

早期的冷卻塔會放在建築物的屋頂,或是獨立的建築物,其冷卻是用風扇進行風冷,或是用自然風冷進行冷卻[4][7]。有一本1911年的美國工程教科書中曾提到一種設計是「圓柱形或長方體的輕形殼狀建築物,類似煙囪,但高度較短(六公尺到十三公尺),寬度寬很多。頂部是一組分配槽,要冷卻的水需要先泵到最上方的分配槽內,由分配槽流到冷卻塔中的木條或編織網上。」[7]

雙曲形冷卻塔是荷蘭工程師Frederik van Iterson和Gerard Kuypers在1918年的專利[8]。第一個雙曲冷卻塔是在1918年建在荷蘭的海爾倫附近。英國的第一個雙曲冷卻塔是在1924年建在英國利物浦的李斯特發電塔,是要冷卻火力發電廠的冷卻水[9]。

依用途分類[编辑]

暖通空調(HVAC)[编辑]

暖通空調(暖氣、通風及空氣調節,簡稱HVAC)的冷卻水塔是用來排除冰水主機的廢熱。水冷的冰水主機排熱溫度在湿球温度附近,而氣冷的冰水主機排熱溫度是在溫度較高的乾球温度,因此後者的平均反卡諾循環效率較低。若是氣溫較高的地區、大型辦公大樓、醫院或學校,其空調系統中一般會有一個或是多個冷卻水塔。空調用的冷卻水塔一般會比工業用的要小。暖通空調會用冷卻水塔配合水冷的冰水主機或是水冷的冷凝器。冷凍噸定義為移除12,000英熱單位每小時(3,500瓦特)的功率。, 但因為驅動冰水主機壓縮機需要額外的能量,在冷卻塔端的「等效冷凍噸」是移除15,000英熱單位每小時(4,400瓦特)的功率。若假設冰水主機性能係數(COP)為4.0(等效於EER 14),其「等效冷凍噸」定義為冷卻1,500英磅每小時(680公斤每小時)的水,使其降10 °F (6 °C),約等於15,000英熱單位每小時(4,400瓦特)[10]。

若HVAC系統中有多個共用水泵管路的水源熱泵,也會使用冷卻水塔。在這類的系統中,只要熱泵運作在冷卻模式下,水環路內的循環水就會移除熱泵中冷凝器中的熱量,而冷卻水塔是冷卻水環路內的循環水,將熱量排到大氣中。相反的,若熱泵是在供暖模式下,冷凝器會抽取水環路中的熱量,排到需要加熱的位置。若熱泵主要是用在大樓供暖,一般會關閉冷卻水塔(並且將水排乾以避免因液體冷凍造成的設備損壞),此時會用其他方式加熱水環路,例如獨立锅炉。

工業冷卻塔[编辑]

工業冷卻塔也會用在移除許多工業程序中的廢熱,例如機械加工的發熱或是加熱材料產生的熱。大型工業冷卻塔的主要用途是用來冷卻在水冷系統中的循環水,水冷系統可能是用在發電廠、煉油廠、石化廠、天然气製造廠、食品加工廠、半導體廠,或是其他的工業設備中,例如蒸餾塔的冷凝器中,結晶製程中的冷卻液等[11]。若是典型 700 MW的燃煤火力發電廠,冷卻水的循環用量約為每小時71,600立方公尺[12],循環水需要的補水供應量約為5%(每小時3,600立方公尺)。

若相同規模的發電廠沒有冷卻塔,使用單流冷卻(once-through cooling)的水冷系統,需要的冷卻水量是每小時100,000立方公尺[13]。大量的冷卻水若流入會造成每年殺死上百萬的鱼及幼体,因為這些生物會撞擊到進水口的魚屏[14]。而且冷卻系統也需要持續地將大量的水排入海洋、湖泊或河流,也就是取得冷卻水源的水體。冷卻系統會排出大量的熱水,會使河流或湖泊水溫上昇,進而影響生態系統,可能會殺死其他水中的生物(參見熱污染)或是造成其他不想要的物種或是入侵物種的繁殖(例如斑馬貽貝或藻類)。冷卻塔的廢熱會散失到空氣中,會透過風和空氣對流擴散到更廣的區域,其溫度影響也較小,不會像冷卻系統的廢熱水,對一區域的水域有較大的影響。蒸發的冷卻水無法在後續回收利用,只有表面冷卻的水可以回收使用。 有些在海邊的燃煤火力發電廠以及核电厂會用海水來單流冷卻,而離岸冷卻水的放流口也需要謹慎設計,以免造成環境問題。

煉油廠也有很大型的冷卻系統。典型每天處理四萬公噸原油的大型煉油廠,若用冷卻塔冷卻,其冷卻水需求是每小時80,000立方公尺。

世界上最高的冷卻塔是印度拉賈斯坦邦贾拉瓦尔卡里森德火力發電廠中,二座202公尺的冷卻塔熱電站[15]。

依興建方式的分類[编辑]

封裝型[编辑]

封裝型(Package type)冷卻塔是小型冷卻塔,在工廠先組裝好,可以直接用卡車運送。其降溫能力較低,只適用在散熱需求較低的應用,例如食品加工廠、紡織廠、部份的化工廠,汽車工廠以及像醫院、旅館、商場等建築物中。

封裝型冷卻塔常常裝設在住宅區內,或是住宅區附近,因此其噪音音量控制就會是比較重要的議題之一。

現場架設的冷卻塔[编辑]

像發電廠、鋼鐵加工廠、煉油廠或是石化廠的散熱需求較高,因此會使用現場架設的冷卻塔。其體積和散熱能力都比封裝型冷卻塔要高。

典型的現場架設的冷卻塔是拉擠成型纖維強化塑膠(FRP)結構、FRP覆層、鼓風冷卻的機械模組,以及擋水器(drift eliminator)。

熱交換方式[编辑]

冷卻塔可以依传热方式分類:

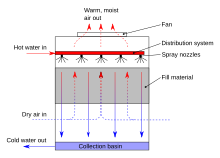

- 濕式冷卻塔(wet cooling towers):其運作的原理是蒸發冷卻。蒸發流體(通常是水)也是工作流體。

- 閉路冷卻塔(closed circuit cooling towers)也稱為流體冷卻器(fluid coolers),會讓工作流體經由管路流進大型的熱交換器中,熱交換器外再噴灑清水並且用風扇通風。其傳熱性能類濕式冷卻塔,好處是工作流體不會暴露在環境中,也不會受到外界的污染。

- 乾型冷卻塔(dry cooling towers)是封閉管路的冷卻塔,工作流體會接到散热器內,由散热器的空氣產生的對流熱傳散熱,沒有用到流體的蒸發。

- 混合冷卻塔(hybrid cooling towers)是可以在乾式和濕式之間切換的封閉管路冷卻塔,可以在不同的氣候下使用,設法作到水和能量之間的節約達到平衡。

若是濕式冷卻塔(或開路冷卻塔),而且在空氣較乾燥的情形下,可以將冷卻水降溫到較室溫乾球温度更低的温度。因為有部份的水會蒸發,蒸發時需要的熱能是由冷卻水提供,因此冷卻水會降溫。水蒸發時需要吸收的熱能是每公斤420kJ。蒸發後會使冷卻水的溫度接近湿球温度,此溫度較乾球温度低,兩者的溫差視原來空氣的濕度而定。

為了提高散熱效果,會在冷卻塔中加入散熱材(fill),以增加水和空氣的接觸面積,以及接觸的時間。濺水散熱材(Splash fill)可以中斷水流,產生濺水。薄膜散熱材用薄膜材料(多半是聚氯乙烯)製成,放置在水流中。兩者都可以增加流體(水)和氣體(空氣)的接觸面積及接觸時間,以提昇散熱。

通風方式[编辑]

依照冷卻塔的通風方式,可以將冷卻塔分為以下三種:

- 自然通風(Natural draft):本身是高的煙囪,利用浮力通風。溫暖、濕潤的空氣其密度比外界較乾冷的空氣要低,因此自然會往上昇。在相同的壓力下,溫暖的濕空氣比乾空氣要輕。濕空氣的浮力會在塔中產生向上的氣流。

- 機械通風:利用風扇通風,使冷卻塔中產生氣流。

- 誘導通風(Induced draft):冷卻塔的機械通風是在冷卻塔上方,由風扇將空氣由塔中排出。風扇讓濕熱的空氣排出塔外,此作法的排氣風速較大,進氣風速較小,比較不會有回流(recirculation,排出的熱空氣又從進氣端進入冷卻塔)的情形。這種風扇/鰭片設計稱為draw-through。

- 強制通風(Forced draft):冷卻塔的機械通風是在冷卻塔下方,風扇在進氣口將空氣送入冷卻塔內,此作法的進氣風速較大,排氣風速較小。較小的排氣風速比較可能會造成回流的問題。而風扇在較低溫空氣的進氣端,在氣溫較低時風扇比較容易會受到結凍的影響。強制通風的另一個缺點是相較於誘導通風,強制通風需要比較大功率的風扇。強制通風的好處是可以在高靜壓下運作。這種設計可以用在空氣較受限的場合,甚至是一些室內的應用中。這種風扇/鰭片設計稱為blow-through。

- 風扇輔助自然通風:主要還是靠自然通風,但再加上風扇的輔助氣流。

雙曲面結構是自然通風冷卻塔常見的設計方式,原因是結構強度以及材料的最小化。雙曲面也可以加速上昇的對流氣流,提昇冷卻效率。此建築常讓人聯想到核电厂,不過這是誤解,因為大型的火力發電廠也會用雙曲結構的冷卻塔。而且不是所有的核電廠都需要冷卻塔,核電廠也可能用湖水、河水或海水進行冷卻。

雙曲結構冷卻塔的熱效率最高可以到92%[16]。

依空氣和水流的關係分類[编辑]

橫流式[编辑]

橫流(Crossflow)式冷卻塔是指氣流和水流垂直的冷卻塔設計(如圖左)。氣流由冷卻塔的一個或多個垂直面進入冷卻塔,吹到散熱材上,水流(和氣流垂直)會因重力沿著散熱材往下流。空氣持續流經散熱材,會越過水流進入開放的通風空間。最後會由風扇將空氣排到大氣中。

橫流式冷卻塔的布水器(distribution)或熱水盆(hot water basin)中會包括深的水盆,下方有洞或噴嘴,水盆在橫流式冷卻塔的上方。水會因為重力透過噴嘴均勻的分佈在散熱材上。

橫流式冷卻塔的優點:

- 因為用重力來讓水均勻分佈,可以使用較小的水泵,運行時需要的維護也比較少。

- 不需加壓噴霧,簡化了水流量的變化。

- 其初期成本以及長期成本都不高。

橫流式冷卻塔的缺點:

- 相較於逆流式的設計,橫流式冷卻塔比較會有結凍的問題。

- 在一些情形下,無法使用變化流量。

- 相較於逆流式的設計,橫流式冷卻塔的散熱材比較容易堆積灰塵,尤其是在塵土或砂石較多的環境。

逆流式[编辑]

逆流式(counterflow)冷卻塔的氣流方向和水流恰好相反。氣流會從散熱材下方進入冷卻塔,垂直往上吹。水會從上方透過加壓噴頭從冷卻塔上方往下噴灑,和氣流方向恰好相反。

逆流式冷卻塔的優點:

- 用加壓噴灑方式布水,比較不會有結凍的問題。

- 用噴灑方式布水,讓熱傳會比較有效率。

逆流式冷卻塔的缺點:

- 由於水泵的需求,初期成本以及長期成本都比較高。

- 不容易使用變化水流量,因為會受到噴嘴特徵的限制

- 散熱材下方到冷水盆的距離較長,因此一般而言會比較吵。

共同的特點[编辑]

兩種設計的共同特點:

- 水流和氣流的交互作用,讓溫度可以局部均衡,也讓水可以蒸發。

- 帶有飽和水蒸氣的空氣,會從冷卻塔的上方排出。

- 會設計集水盆(collection basin)或冷水盆(cold water basin)來收集並儲存和氣流交互作用後的冷氷。

橫流式和逆流式冷卻塔都可以用在自然對流以及機械對流的冷卻塔中。

濕式冷卻塔的質量平衡[编辑]

以量化的觀點,濕式蒸發冷卻塔的質量平衡是淡水補充體積流率、蒸发損失、風損失、出汽率和濃縮倍數(concentration cycles)等操作變數所控制[17][18]。

在旁邊的圖中,從tower basin抽到的水是流經工廠的製程冷卻器以及表面冷凝器的冷卻水。冷水會從熱的、需要冷卻或是冷凝的製程蒸氣中吸熱,吸收的熱會使冷卻水(C)加溫。溫水會回到冷卻塔的上方,再往下滴入下方塔內的填充材料中。在水滴下來的過程中,會和經由自然通風或因風扇強制通風而上昇的室溫空氣接觸。接觸會使得一部份的水因為風而損失(windage drift loss,W),也有一些水會蒸发(E)。蒸發水需要吸熱,會使其他的水降溫,可以繼續冷卻循環。不過水蒸發後會留下其中溶解的盐,因此會使得循環水的鹽濃度提高。為了避免循環水中鹽的濃度過高,需要將部份的水排出(D),另外再補充淡水(M),以補償蒸發、風損以及排出的水。

以下是流率以及濃度的單位:

| M | = 需補充淡水率,單位是m3/h |

| C | = 單位時間循環水量,單位是m3/h |

| D | = 排水率,單位是m3/h |

| E | = 蒸發率,單位是m3/h |

| W | = 水風損損失率,單位是m3/h |

| X | = 濃度,單位是ppmw)(針對完全可溶的鹽,一般是氯化鈉) |

| XM | = 補充水(M)氯化物的濃度,單位是ppmw |

| XC | = 循環水(C)氯化物的濃度,單位是ppmw |

| Cycles | = 濃縮倍數= XC / XM(無因次量) |

| ppmw | = 重量的百萬分之一 |

整個系統的水平衡可得[18]:

- M = E + D + W

蒸發水(E)中沒有鹽,因此氯化物的平衡如下[18]:

- MXM = DXC + WXC = XC(D + W)

因此[18]

用簡化的冷卻塔熱平衡式:

| where: | |

| HV | = 水蒸發的潛熱,2260 kJ / kg |

| ΔT | = 從塔頂到塔底的溫度差,單位°C |

| cp | = 水的比熱,4.184 kJ / (kg°C) |

風損(W)是因為氣流而減少的水量。若沒有製造商的數據,大型的工業冷卻塔,可以假設如下:

- 若是自然通風,沒有風損消除器(windage drift eliminators),W = C的0.3%至1.0%。

- 若是誘導通風,沒有風損消除器,W = C的0.1%至0.3%。

- 若有風損消除器,W = C的0.005%以下。

- 若有風損消除器,且用海水作為補充水,W = C的0.0005%以下。

濃縮倍數[编辑]

濃縮倍數表示循環水中溶解礦物質的累積程度。一般會用排放冷卻水來控制這些礦物質的生成。

補充水的化學特性(包括溶解礦物質的量),其變化範圍很廣。若是從表面水體(湖水、河水)取得的補充水,比較容易腐蝕金屬,若是由地下水(例如水井)取得的補充水,礦物質較高,比較容易有水垢的問題。若增加水中礦物質的量,比較不容易腐蝕管路,不過可能會有水垢。

當濃縮倍數增加時,水中溶解的礦物質可能會超過其溶解度,因而沉淀礦物質固體,會因此而結垢,也會造成冷卻塔或是换热器的問題。循環水的溫度、管路以及熱交換器的表面都會決定循環水的礦物質是否會沈澱,以及在何處沈澱。專業的工業水處理顧問可以評估冷卻塔的工作條件以及補充水量,並且建議適當的濃縮倍數。使用水處理化合物、進行硬水软化、PH值調整等預處理等技術,都會影響濃縮倍數的允許範圍。

冷卻塔的濃縮倍數多半是在3到7之間,美國許多的供水是使用井水,其溶解礦物質較多。另外,紐約最大的供水系統是用雨水,其溶解礦物質很低,因此其濃縮倍數可以到7,甚至可以超過7。

因為濃縮倍數高表示補充水可以較少,節水措施一般會著重在提高濃縮倍數[19]。若在飲用水稀缺的地區,冷卻水使用高度處理的循環水,可以減少在飲用水上的使用[20]。

維護[编辑]

冷卻塔的冷水盤和表面需清潔,去除可見的塵土和碎屑,並且去肉眼可見的生物薄膜[來源請求]。

需維持冷卻塔及熱水管中的消毒劑以及其他化學物的含量,並且持續監控[21]。

需要定期用浸片針對水質(特別是好氧菌)進行檢查,因為其他的生物可能會產生營養物質,讓軍團菌可以存活[來源請求]。

水處理[编辑]

在大型的工業冷卻系統中,除了處理循環水以減少水垢外,循環水也需要經過過濾,以去除雜質,也會加入殺生物劑和除藻劑,以避免這些生物的滋長,進而影響水的連續流動[17]。在一些特定條件下,冷卻水中可能會生成由細菌、真菌或藻類形成的生物薄膜,若這類生物迅速生長,會降低冷卻塔的熱傳效率。利用氯或是其他的化學物質,可以減少或是預防生物薄膜的生成。工業上常見的作法是用二種的殺生物劑,例如一種是氧化型的,另一個是非氧化型,二種殺生物劑可以截長補短,以確保有較廣的防護範圍。大部份的情形,會持續使用少量的氧化型殺生物劑,再週期性的加入大量的非氧化型殺生物劑[來源請求]。

冷卻水會因為排水、氣損及蒸發而散失。因此會預備補充水以維持水量,其目的是讓機械及設備可以安全穩定運轉。

军团病[编辑]

冷卻塔使用殺生物劑的另一個原因是避免軍團菌屬細菌的生長,特別是會造成军团病(退伍軍人症)的菌種,嗜肺军团菌(L. pneumophila)[22],或是鳥型結核分枝桿菌[23]。軍團菌屬細菌會造成军团病,此疾病可以透過空氣中的懸浮粒子傳播,因此吸入含有病菌液滴的空氣即可能感染。軍團菌屬細菌的常見來源包括開放循環蒸發的冷卻水系統,家用熱水系統、噴泉,或是其他公用給水系統。自然的來源可能包括淡水池或是溪流[24][25]。

法國研究者指出在法國加来海峡省的石化廠冷卻塔中,其中的冷卻水含有軍團菌屬細菌,細菌可以透過空氣傳播6公里(3.7英里)的距離。曾經爆發感染,86人經實驗室檢驗,判斷確診,其中有21人死亡[26]。

風損(Drift或windage)是指冷卻塔排出,在空氣中以液滴形式散失的水份。風損消除器可以讓風損維持在循環水流量的0.001–0.005%。標準的風損消除器會讓氣流有多方向的變化,避免液滴從冷卻塔排出。設計良好,而且適合冷卻塔的風損消除器可以大幅降低風損,也可以降低軍團菌屬細菌暴露或是水處理化學藥暴露的風險。每六個月需要檢查風損消除器,確定其中沒有縫隙,以避免污物自由流動[27]。

美国疾病控制与预防中心(CDC)不建議醫療機構定期針對軍團菌屬細菌進行檢查。是否要針對軍團菌屬細菌定期進行微生物監控,仍有爭議,因為有軍團菌屬細菌不代表會產生疾病。針對已知會傳播軍團菌屬細菌的設備,美国疾病控制与预防中心建議進行積極的消毒措施,但不建議對細菌進行定期的微生物檢測。不過若醫院中的病患在特殊的條件(例如造血干细胞移植中心、器官移植中心)容易受到軍團菌屬細菌感染而患病甚至死亡,需考慮對飲用水進行定期的監測。另外,在軍團菌屬暴發後,衛生官員同意有必要監控以來識別感染源,並且評估殺生物劑或是其他預防措施的效果[28][與來源不符]。

研究指出冷卻塔中有40%至60%含有軍團菌屬細菌[29]。

產生的霧[编辑]

在特定的環境條件下,會看到水蒸氣的氣流從冷卻塔的排氣口排出,可能會誤認為是火災產生的煙。若室外空氣的水蒸氣已飽和或接近飽和,冷卻塔又增加空氣中的水氣,會排出帶有水液滴及飽和水蒸氣的空氣,即為霧。此現象一般會發生在濕冷的天氣,不過在許多氣候下都很少見。和冷卻塔有關的雲和霧其特點是其均質性,就像其他人造的雲一樣(例如飛機雲及船跡)[30]。

若是降低排放飽和空氣的相對濕度,可以避免此一情形。因此,在混合式冷卻塔中,會將排放飽和空氣和較熱、濕度較低的空氣混合。會在風損消除器的上方導入一些空氣,使其在熱交換器中流動。相對濕度較低的乾空氣在進入塔內後,會因為加熱而讓相對濕度進一步降低。排出的混合氣體相對濕度較低,也不會形成肉眼可見的霧。

排放鹽類及其他物質的污染[编辑]

若在海邊(或靠近海邊),用海水作為補充水的濕式冷卻塔,冷卻塔排放的水液滴中會含有6%的氯化鈉,會散播在附近的陸地上。鈉鹽在附近農地上的沈積,可能會將會將土壤變為鹽化鈉質土或盐碱地,並且增加地下水以及表面水的鈉吸著比。在沒有國家級污染控制標準的地區,或是沒有採取措施來降低濕式冷卻塔風損的地區,若使用海水作為補充水,其鹽分沉積的問題會更嚴重[31]。

若使用淡水補充水,不會有排放鹽類的問題,可是會有其他問題。冷卻塔的風損水液滴中,可能會有直徑小於10微米(µm)的可吸入懸浮粒子。10微米以上的懸浮粒子會在鼻子和喉嚨中被纖毛和粘液過濾,但較小的粒子(PM10)會進入支氣管以及肺部,因而形成健康問題。大小小於2.5 µm(PM2.5)的粒子會進入肺部的氣體交換區域。非常小的粒子(小於100奈米)會經由肺部進入體內循環,影響其他器官。雖用淡水補充水的總粒子排放會少很多,但其中PM10和PM2.5的比例會比以海水為補充水時要多很多。這是淡水為補充水的風損鹽份(小於2,000 ppm)較用海水時(60,000 ppm)要少[31]。

用作排氣煙囪[编辑]

有些現代的發電廠有配置煙氣脫硫設備,例如Großkrotzenburg發電廠和羅斯托克發電廠,也會用冷卻塔當成排氣煙囪,因此可以節省獨立煙囪結構的費用。若發電廠沒有煙氣淨化設備,煙氣和水可以會反應產生酸,因此會出現腐蝕的問題。

有時自然通風的冷卻塔會用結構鋼來代替鋼筋凝混凝土(RCC)來建造,多半是在自然通風冷卻塔的建造時間超過其他設備建造時間時,或是當時的土壤強度不足,無法承載結構鋼和混凝土結構的重量,也有可能因為混凝土價格昂貴,為了成本考量,因此用結構鋼來製作冷卻塔。

火災危害[编辑]

若冷卻塔中的部份材料(或全部材料)有可燃物質,可能會助長內部火災的擴散。因為冷卻塔內部的高表面體積比,再加上自然通風或強制通風的影響,其火勢會相當的強。其損害會相當嚴重,需要更換冷卻塔內的所有元件。因此有些製作規模或標準[32]會要求可燃的冷卻塔需加裝自動灑水系統。若冷卻塔沒有運作(例如正在興建中,或因維修原因沒有運作),內部的火災可能會蔓延,甚至在冷卻塔有運作時,針對誘導通風的系統,可能會因為部份區域相對來說較乾,而可能產生火災[33]。

低溫環境下的處理[编辑]

有些冷卻塔(例如較小型的大樓空調系統)為了避免結凍造成的損害,會在冬季關機、將水排空並且防凍。

在冬季時,有些持續運作的冷卻塔會使流出的水溫度在4 °C(39 °F)。針對寒冷的天氣,會使用Basin加熱器等防凍的對策。在運作中的冷卻塔在天氣非常寒冷時也可能會誤動作。一般來說,結凍會先出現在冷卻塔的中央,在熱負載較小,或是沒有熱負載時出現。嚴重的結凍會讓水變成冰,其體積膨脹,因此會增加結構上的受力,可能會造成結構受損或是倒塌。

為了避免結凍,可以採取以下的措施:

- 在寒冷的天氣中,不建議使用水量調節的旁路(by-pass)系統。此時需要有變速馬達的控制可變性、雙速馬達、或是雙速馬達多芯冷卻塔[來源請求]。

- 不要在沒有監控的情形下運作冷卻塔。若無人看守,需要加裝感測器及遠端的警報器以監控運作情形。

- 不要在沒有水壓的情形下運作冷卻塔。可以用讓冷卻塔中的水維持在凝固點以上。加熱管是電阻性的發熱元件,可以裝在水管上以避免結凍。

- 讓水的流量可以超過塔內的填充料。

- 控制或減少氣流,以維持水溫在凝固點以上[來源請求]。

結構穩定性[编辑]

非常大的冷卻塔很容易因風力而受損,過去也曾發生過大型結構的失效。英國西约克郡的渡橋發電站在1965年11月1日,因為85 mph(137 km/h)強風造成的振動,造成三座冷卻塔結構失效而倒塌[34]。此結構的設計是可以承受較高的風速,但冷卻塔的形狀導致西風漏斗狀的繞著塔旋轉,形成渦旋。八座冷卻塔中有三座倒塌,另外五座也嚴重受損。後來八座冷卻塔都已重建,而且有強化,可以承受惡劣的天候。後來也有修改建築法規,其中包括改善結構支撐,以及為了確認冷卻塔的結構和組態,需進行风洞測試[來源請求]。

相關條目[编辑]

參考資料[编辑]

- ^ CleanEnergy Footprints (cleanenergy.org). Identifying Nuclear Reactors in Google Earth (页面存档备份,存于互联网档案馆) Retrieved 5/19/2014

- ^ 2.0 2.1 International Correspondence Schools. A Textbook on Steam Engineering. Scranton, Pa.: International Textbook Co. 1902. 33–34 of Section 29:"Condensers".

- ^ Croft, Terrell (编). Steam-Engine Principles and Practice. New York: McGraw-Hill. 1922: 283–286.

- ^ 4.0 4.1 4.2 Heck, Robert Culbertson Hays. The Steam Engine and Turbine: A Text-Book for Engineering Colleges. New York: D. Van Nostrand. 1911: 569–570.

- ^ 5.0 5.1 Watson, Egbert P. Power plant and allied industries. The Engineer (With Which is Incorporated Steam Engineering) (Chicago: Taylor Publishing Co.). 1906, 43 (1): 69–72 [2021-02-13]. (原始内容存档于2020-07-29).

- ^ van Vliet, Michelle T. H.; Wiberg, David; Leduc, Sylvain; Riahi, Keywan. Power-generation system vulnerability and adaptation to changes in climate and water resources. Nature Climate Change. 2016, 6 (4): 375–380. ISSN 1758-678X. doi:10.1038/nclimate2903.

- ^ 7.0 7.1 7.2 Snow, Walter B. The Steam Engine: A Practical Guide to the Construction, Operation, and care of Steam Engines, Steam Turbines, and Their Accessories. Chicago: American School of Correspondence. 1908: 43–46.

- ^ UK Patent No. 108,863. [2021-02-13]. (原始内容存档于2009-02-05).

- ^ Power Plant Cooling Tower Like Big Milk Bottle. Popular Mechanics (Hearst Magazines). February 1930: 201 [2021-02-13]. ISSN 0032-4558. (原始内容存档于2020-07-29).

- ^ Cheremisinoff, Nicholas. Handbook of Chemical Processing Equipment. Butterworth-Heinemann. 2000: 69. ISBN 9780080523828.

- ^ U.S. Environmental Protection Agency (EPA). Profile of the Fossil Fuel Electric Power Generation Industry (报告). Washington, D.C. 1997 [2021-02-13]. (原始内容存档于2011-04-05). Document No. EPA/310-R-97-007. p. 79.

- ^ Cooling System Retrofit Costs (页面存档备份,存于互联网档案馆) EPA Workshop on Cooling Water Intake Technologies, John Maulbetsch, Maulbetsch Consulting, May 2003

- ^ Thomas J. Feeley, III, Lindsay Green, James T. Murphy, Jeffrey Hoffmann, and Barbara A. Carney (2005). "Department of Energy/Office of Fossil Energy’s Power Plant Water Management R&D Program." 互联网档案馆的存檔,存档日期27 September 2007. U.S. Department of Energy, July 2005.

- ^ Indian Point Energy Center的冷卻系統每年會殺死十億個魚卵及幼体McGeehan, Patrick. Fire Prompts Renewed Calls to Close the Indian Point Nuclear Plant. New York Times. 2015-05-12 [2021-02-13]. (原始内容存档于2019-09-11).

- ^ 存档副本. [2021-02-13]. (原始内容存档于2018-12-12).

- ^ Gul, S. Optimizing the performance of Hybrid: Induced-Forced Draft Cooling Tower. Journal of the Pakistan Institute of Chemical Engineers. 2015-06-18, 43 (2) [2021-03-07]. ISSN 1813-4092. (原始内容存档于2018-06-22) (英语).

- ^ 17.0 17.1 Beychok, Milton R. Aqueous Wastes from Petroleum and Petrochemical Plants 1st. John Wiley and Sons. 1967. LCCN 67019834.

- ^ 18.0 18.1 18.2 18.3 Milton R. Beychok. How To Calculate Cooling Tower Control Variables. Petroleum Processing. October 1952: 1452–1456.

- ^ Best Management Practice Cooling Tower Management. Energy.gov. Department of Energy. 30 April 2005 [16 June 2014]. (原始内容存档于2014-07-24).

- ^ San Diego County Water Authority. Technical Information for Cooling Towers Using Recycled Water (PDF). www.sdcwa.org (San Diego County Water Authority). July 2009 [18 June 2014]. (原始内容存档 (PDF)于2021-01-15).

- ^ Developing a Water Management Program to Reduce Legionella Growth & Spread in Buildings: A Practical Guide to Implementing Industry Standards (PDF). CDC: 13 {17 of 32. 5 June 2017.}

- ^ Ryan K.J.; Ray C.G. (editors). Sherris Medical Microbiology 4th. McGraw Hill. 2004. ISBN 978-0-8385-8529-0.

- ^ Centers for Disease Control and Prevention – Emerging Infectious Diseases (页面存档备份,存于互联网档案馆) (page 495)

- ^ Cunha, BA; Burillo, A; Bouza, E. Legionnaires' disease.. Lancet. 23 January 2016, 387 (10016): 376–85. PMID 26231463. doi:10.1016/s0140-6736(15)60078-2.

- ^ Legionella (Legionnaires' Disease and Pontiac Fever) About the Disease. CDC. 26 January 2016 [17 June 2017]. (原始内容存档于2016-03-25).

- ^ Airborne Legionella May Travel Several Kilometres (access requires free registration)

- ^ Delta Cooling Towers, Inc., July 2020. Page 1 of 1, section 6, paragraph 2.. [2021-04-29]. (原始内容存档于2021-04-30).

- ^ CDC Guidelines for Environmental Infection Control in Health-Care Facilities, pages 223 & 224, Water Sampling Strategies and Culture Techniques for Detecting Legionellae (PDF). [2021-04-29]. (原始内容存档 (PDF)于2017-05-21).

- ^ Cooling Tower Institute, July 2008. Page 5 of 12, column 1, paragraph 3. Most professional and government agencies do not recommend testing for Legionella bacteria on a routine basis. (PDF). [2021-04-29]. (原始内容存档 (PDF)于2021-05-13).

- ^ Sutherland, Scott. Cloud Atlas leaps into 21st century with 12 new cloud types. The Weather Network. Pelmorex Media. 23 March 2017 [24 March 2017]. (原始内容存档于2022-05-31).

- ^ 31.0 31.1 Wet Cooling Tower Guidance For Particulate Matter, Environment Canada 互联网档案馆的存檔,存档日期3 April 2015., Retrieved on 2013-01-29

- ^ National Fire Protection Association (NFPA). NFPA 214, Standard on Water-Cooling Towers (页面存档备份,存于互联网档案馆).

- ^ NFPA 214, Standard on Water-Cooling Towers. (页面存档备份,存于互联网档案馆) Section A1.1

- ^ Ferrybridge C Power Station officially closes after 50 years. [2021-03-08]. (原始内容存档于2020-06-12).

外部連結[编辑]

- What is a cooling tower? (页面存档备份,存于互联网档案馆) – Cooling Technology Institute

- "Cooling Towers" – includes diagrams (页面存档备份,存于互联网档案馆) – Virtual Nuclear Tourist

- Wet cooling tower guidance for particulate matter, Environment Canada.

- Striking pictures of Europe’s abandoned cooling towers (页面存档备份,存于互联网档案馆) by Reginald Van de Velde, Lonely Planet, 15 February 2017 (see also excerpt from radio interview (页面存档备份,存于互联网档案馆), World Update, BBC, 21 November 2016)

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||

| ||||||||||||